The 3D Printers are a magical printer designed by an inventor named Enrico Dini that can not only "print" an entire building, but can even print astronauts anything they need in a space shuttle. At present,3D printing has become a trend, and began to be widely used in the field of design, especially in industrial design, digital product mold opening, etc., can be completed in a few hours to print a mold, saving a lot of product to market development time.

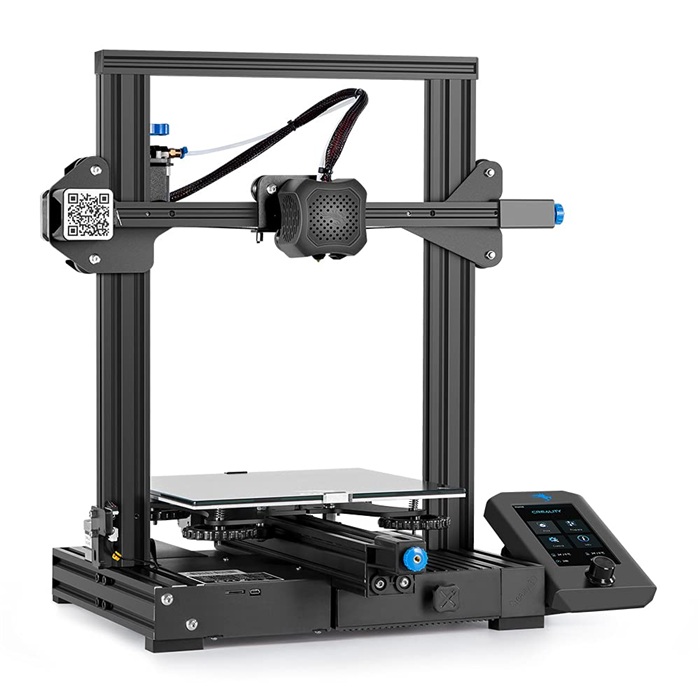

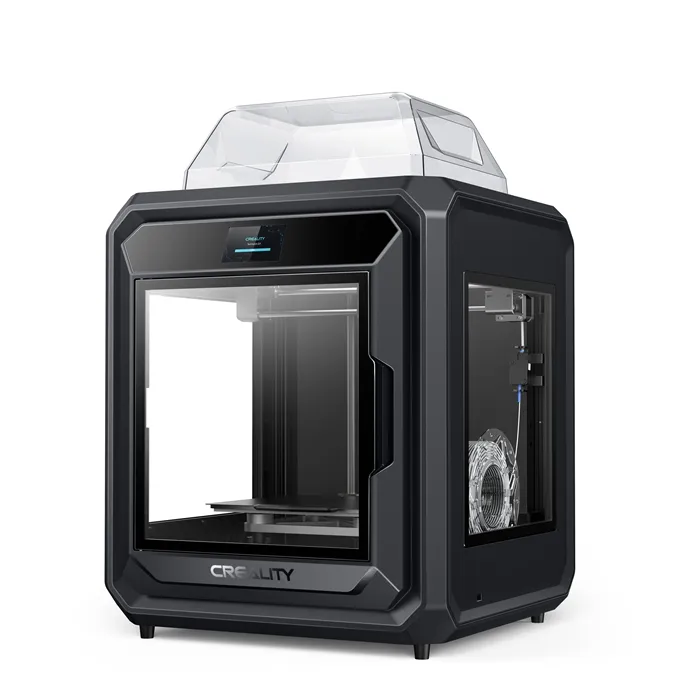

3D printer, also known as three-dimensional printer (3DP), is a kind of cumulative manufacturing technology, that is, a machine of rapid prototyping technology. It is based on a digital model file and can be bonded using special wax, powdered metal or plastic. materials, which create three-dimensional objects by printing layers of adhesive material. 3D printers are currently used to manufacture products. The technique of constructing objects in a layer-by-layer manner. The principle of the 3D printer is to put data and raw materials into the 3D printer, and the machine will build the product layer by layer according to the program.

The difference between a 3D printer and a traditional is that the "ink" it uses is a real raw material, there are various forms of stacking thin layers, and it can be used for printing on a variety of media, from a wide variety of plastics to metals, ceramics and rubber. class substances. Some printers can also combine different media, so that the printed object is hard on one side and hard on the other.

A soft head.

1. Some 3D printers use the "inkjet" method. That is, a very thin layer of liquid plastic substance is sprayed on the casting tray using a printer nozzle, and the coating is then exposed to UV light for treatment. The moulding tray is then lowered a very small distance for the next layer to be stacked.

2. Others use a technology called "deposition molding". The whole process is to melt plastic in the nozzle, and then form a thin layer by depositing plastic fibers.

3. There are also systems that use a technique called "laser sintering" using powder particles as the print medium. Powder particles are sprayed onto a casting tray to form an extremely thin layer of powder, which is cast into a specified shape and then cured by the sprayed liquid binder.

4. Some use electron flow in vacuum to melt powder particles. When encountering complex structures including holes and cantilevers, gelling agents or other substances need to be added to the medium to provide support or to occupy space. This part of the powder is not cast, and the pores are formed by simply flushing the support off with water or air flow.