Why Consider an Ortur Laser Engraver?

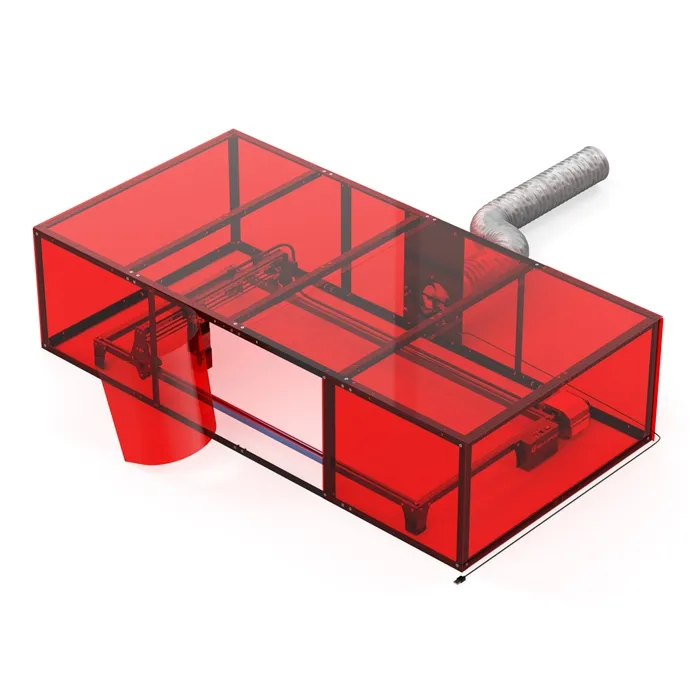

They Are a Great Tool for All Kinds of Jobs Ortur Laser Master 3 Laser Cutting Model

Laser engraver and laser cutting machines have long been regarded as one of the most versatile machines on the market. Until recently, however, the price and cost of ownership has been prohibitive for all but the largest companies. Now, with the introduction of glass tube lasers, that has changed dramatically. This makes laser machines easily accessible to startups on a budget, and more specialized lasers (RF and fiber lasers) are also available.

When you start thinking about the materials these machines can handle, the possibilities are huge. That's why there is so much excitement about them!

When discussing wood and other fibrous materials, it's worth noting that our lasers leave featherless cuts. No "post-processing" is required to sand the edges. This is a major advantage over other machines like routers.

The Ortur Laser Master 3 laser engraver is equipped with software that can accept many common data formats - these can be generated by software such as LightBurn, Photoshop, and numerous "free" graphics packages. All professional CAD software can output files that can be used for cutting on these laser machines.

Ortur laser engraver will accurately mark and engrave most plastics, wood, plywood and MDF, ceramics and stone, glass, card and paper, fabrics, and many other materials; even the Ortur Laser Master 2, which has been on the market for several years, is very capable of cutting most of them. The thickness that can be processed depends largely on the output power. For the cutting of materials such as metals, we offer a range of technologies, from fiber lasers and plasma cutters to water jet cutters and specialized machines for specific applications.

HTPOW offers a range of laser engraving machines from various brands of machine types and sizes and various powers - please contact HTPOW for more information or visit our product page.Are They the Best Machines for The Job?

It depends on your specific needs. First and foremost, a laser is basically a 2D machine; if you need to cut accurately to precise depths, not engrave, score or cut material, then it's not for you. Our lasers have excellent control over laser power, resulting in very good, sharp engraved images, however, the nature of the laser beam makes it difficult to "machine" to precise depths as you would with a milling machine.

Lasers are cut by burning or evaporating material, leaving burnt-colored vertical edges on some jobs, especially wood and cardboard. This can be an advantage to give the piece a decorative effect, or further processing (painting, etc.) to hide this effect if desired.

A note on plastics...

Our laser machines have advantages when working with transparent hard plastics such as acrylic. They produce crisp, clean "polished" cut edges that are so good that you can usually get the job done "straight from the machine". You can find more information on acrylics and other plastics on the related materials page.

Care needs to be taken when processing soft plastics. A few, such as PVC and vinyl, produce dangerous by-products. These should not be machined with a laser. The best machine for handling these materials is a "knife plotter" or vinyl plotter.

Laser technology is really great in its wide range of uses and applications, but don't take our word for it, see what our users are saying