September 9, Shenzhen - Creality 3D, the world's leading 3D printer brand, and BASF 3D printing solutions (BASF Forward AM) have officially reached a partnership to jointly expand the quasi-industrial additive manufacturing market. Creality 3D also launched Sermoon D3, a fully enclosed FDM 3D printer, and HP-ULTRA, a series of high-end brand consumables jointly customized for Creality 3D printers.

Creality 3D and BASF Forward AM give full play to each other's professional capabilities, jointly develop and promote the joint consumable series including HP-ULTRA PLA and HP-ULTRA ABS, and have a good understanding of HP-ULTRA's application in Creality 3D quasi-industrial printers. The performance has been tested and optimized. The two parties will also cooperate closely in broadening the application scenarios of additive manufacturing, and are committed to the industrialization and upgrading of additive manufacturing in industries such as manufacturing, automotive, medical and education.

Liu Huilin, co-founder and executive director of Shenzhen Creality 3D Technology Co., Ltd. said: "BASF Forward AM is a global giant in chemical materials and has profound industry experience in the material field. Creality 3D has always focused on the 3D printing industry. Deep cultivation has an iconic influence in the global 3D printing industry. The strategic cooperation between the two parties in the field of 3D printing consumables has broadened the application scope of quasi-industrial 3D printers. For example, the new product Sermoon D3 released this time is this strategic cooperation The latest research and development results.”

Dr. Chen Li, Director of Business and Operations, Forward AM Asia Pacific, BASF, said: "The two sides have a high degree of compatibility in promoting the industrialization of additive manufacturing, so they decided to join hands to enter the quasi-industrial additive manufacturing market and create solutions that meet the needs of quasi-industrial customers. I firmly believe that the powerful combination of the two parties will surely provide customers with more professional, cost-effective and widely used additive manufacturing solutions."

Sermoon D3 - Born for Industrial Design

Companies that use traditional methods in prototyping and design verification face pain points such as long R&D cycles, high costs, limited material options, and material waste due to mold opening failures. Sermoon D3, as the latest achievement of Creality 3D in the quasi-industrial market, has industrial-grade stability, and has passed the test and certification of BASF's Forward AM Additive Manufacturing Technology Center (AMTC). Come to cost-effective 3D printing solutions.

Taking the traditional mechanical design process as an example, the traditional design, review, proofing and modification process takes at least 20 working days. However, through 3D printing technology, users can achieve rapid prototyping within 10 working days, shortening the development cycle and improving work efficiency.

Among them, one of the pain points faced by enterprises is the limitation of material selection during product design prototype verification, which greatly affects the adequacy of verification and the competitiveness of enterprises. In response to this problem, Creality 3D and AMTC have verified more than 20 kinds of consumables, and selected 14 of them as the main consumables of Sermoon D3, including strength consumables PA66, ASA, PC and wear-resistant consumables PA66-CF, PET-CF, etc. . Sermoon D3 is currently the model that supports the most types of consumables in the entire series of 3D printers of Creality 3D.

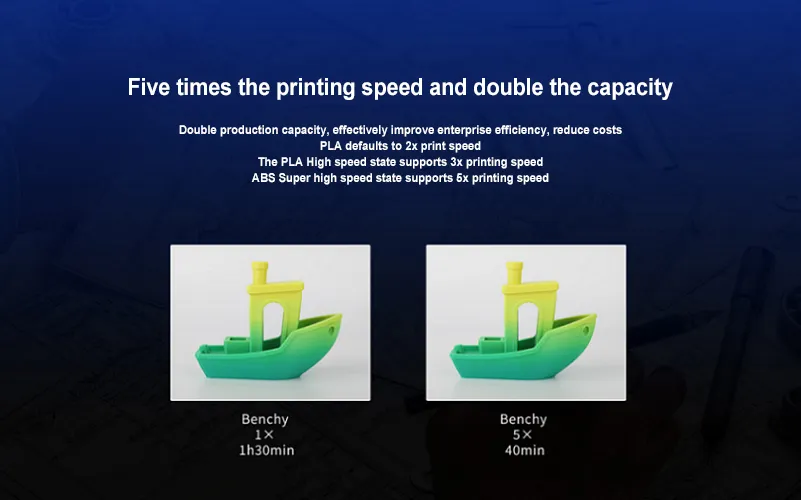

As an important part of Crescendo's "Better Consumables Program", the HP-ULTRA brand consumables series specially designed for Sermoon D3 include various types such as PLA and ABS, and are jointly developed by Creality3D and BASF Forward AM. "Better Consumables Program" is a solution initiated by Creality 3D in cooperation with industry-leading material suppliers, dedicated to providing users with high-quality 3D printing consumables. HP-ULTRA has been fully tested on Sermoon D3 by Creative 3D Labs and ATMC, and users can achieve successful printing without additional adjustment of printing parameters. HP-ULTRA ABS will be included as a free consumable for Sermoon D3.

As an important part of Crescendo's "Better Consumables Program", the HP-ULTRA brand consumables series specially designed for Sermoon D3 include various types such as PLA and ABS, and are jointly developed by Creality3D and BASF Forward AM. "Better Consumables Program" is a solution initiated by Creality 3D in cooperation with industry-leading material suppliers, dedicated to providing users with high-quality 3D printing consumables. HP-ULTRA has been fully tested on Sermoon D3 by Creative 3D Labs and ATMC, and users can achieve successful printing without additional adjustment of printing parameters. HP-ULTRA ABS will be included as a free consumable for Sermoon D3.

Introduction to Creality 3D

Shenzhen Creality 3D Technology Co., Ltd. is a leading brand of 3D printers in the world, focusing on the research and development and production of consumer-grade and professional-grade 3D printers and accessories. Adhering to the development concept of "user-centered", Creality 3D products are exported to 192 countries and regions, providing cost-effective 3D printing solutions for individuals, families, schools and enterprises, and promoting manufacturing, education, medical, Digitization in construction and other fields. As an evangelist in the 3D printing industry, Creality 3D will continue to cultivate cutting-edge technology and bring high-quality product experience to individual and enterprise users. For more information, please visit: https://www.htpow.net/laser-engraving-machine.

About BASF Forward AM

Headquartered in Heidelberg, Germany, BASF 3D Printing Solutions Co., Ltd. is a wholly-owned subsidiary of BASF New Industry Co., Ltd. Through the Forward AM brand, it focuses on the development and business expansion of advanced materials, system solutions, components and services in the field of 3D printing. With a flexible and dynamic internal structure, the company meets the needs of customers in the ever-changing 3D printing market. The company works closely with BASF's global research platform and applied technology divisions, as well as with research institutes, universities, startups and industry partners. Its potential customers are primarily companies working on the use of 3D printing for industrial manufacturing, with typical industries serving include automotive, aerospace and consumer goods. For more information, please visit https://www.htpow.net/3d-printer.