The laser engraving machine market size is growing at a faster rate over the past few years with a high growth rate and the market is expected to grow significantly over the forecast period i.e. 2022 to 2030.

During laser engraver, a laser beam strikes the material, exposing it to considerable heat. Colors change and provide contrast based on exposure time or when the substance evaporates or burns. The resulting laser engraving is durable and wear-resistant. The growing popularity of laser marking in end-user verticals and the performance of laser marking machines over traditional materials are the major factors driving the growth of this market.

Market size and forecast of home laser engraving machine

For Detailed Analysis:

Definition of Global Laser Engraving Machine Market

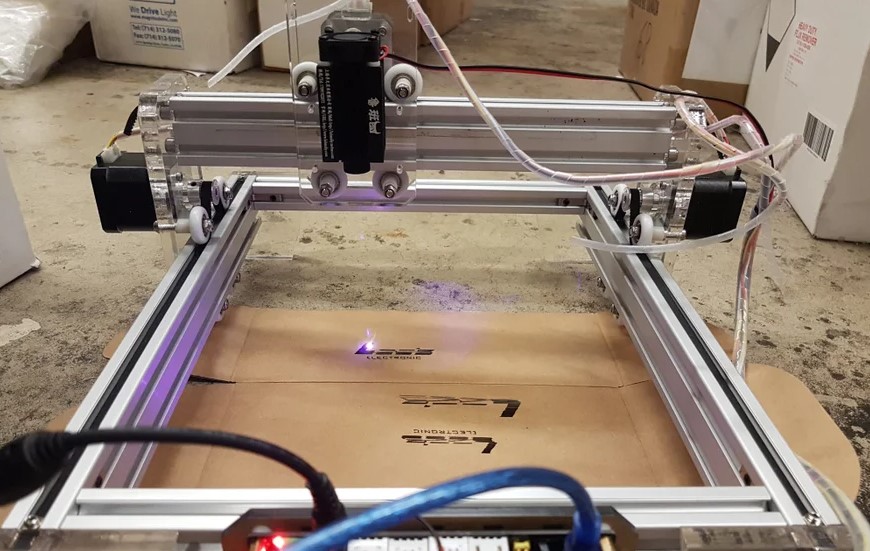

The term "laser engraving" refers to a subset of the term "laser marking". Using a laser to engrave an item is known as laser engraving. A laser engraving machine consists of three main components: the laser, the controller, and the work surface. The laser has the appearance of a pen. The controller uses the laser beam to trace patterns on the surface of the object. The laser beam is aimed at the surface, and the controller uses a computer to adjust the direction, intensity, speed of movement and spread of the laser beam. Surfaces are selected to be compatible with the capabilities of the laser. Natural materials such as wood, plastic, metal, stone, glass jewelry can be engraved.

Laser engraving cutting is used to engrave a specific image or logo onto a selected material. This is a subtractive production technique. However, before the engraving process can begin, the files from the computer must be transferred to the machine controller, and then the laser parameters must be set. When the laser engraving process begins, the beam generates a lot of heat, which burns or vaporizes the surface of the picture in the file. There are two types of engraving: line engraving and surface engraving. The first uses vector graphics to follow a route or line, while the second vaporizes material to embed images or give designs a three-dimensional look.

Laser engraving technology is often used in manufacturing operations to engrave barcodes on various items. The benefit of engraving is that even if the part is used in production or other activities, the barcode will not wear out and it may still be scanned for company reasons. Other markings, such as QR codes, are often used in conjunction with engraving techniques. The jewelry industry also uses laser technology as it provides precise engraving work. It enables them to deliver custom engravings to consumers in a timely manner. Parts in the electrical and medical industries must always be identifiable. These pieces are often laser engraved to provide easy and precise identification.

Global Home Laser Engraving Machine Market Overview

The global home laser engraving machine market is expected to grow over the forecast period owing to increasing demand for rapid production, increasing adoption of laser engraving, and enhanced performance of laser engraving machines over traditional materials. In addition, fast manufacturing processes and increasing popularity of fiber lasers in applications are propelling the market growth. However, high deployment costs and lack of skilled professionals are major restraining factors for market growth.

Global Home Laser Engraving Machine Market: Segmentation Analysis

The global laser engraving machine market is segmented on the basis of product type, application, and geography.

- Market segmentation analysis of laser engraving machine

- Laser Engraving Machine Market, By Product Type

- Diode Laser Engraving Machine

- CO2 Laser Engraver

- Fiber Laser Engraving Machine

- Nd:YAG Laser Engraving Machine

- Laser Engraving Machine Market by Product Type

Based on product type, the market is segmented into diode laser engraving machines, CO2 laser engraving machines, fiber laser engraving machines, and Nd:YAG laser engraving machines. Diode laser engraving machines are expected to witness the largest growth over the forecast period owing to their increased usage in heat treatment applications and their significant energy savings compared to other products.

Laser Engraving Machine Market, By Application

- Printing and packaging

- Advertising decoration

- Leather clothing

- Model making

- Crafts

- Other

On the basis of application, the market is segmented into printing and packaging, advertising decoration, leather apparel, model making, handicrafts, and others. Printing and packaging is expected to grow the most during the show due to shorter deadlines due to ease of product identification, tracking and security.

Home Laser Engraving Machine Market, By Geography

- North America

- Europe

- Asia-Pacific

- Rest of the world

- Laser Engraving Machine Market by Region

Based on geography, the global laser engraving machine market is segmented into North America, Europe, Asia Pacific, and Rest of the World. The global laser engraving machine market in Asia Pacific is expected to grow the most over the forecast period owing to the adoption of laser manufacturing products and solutions, increasing investment in research and development, and growth in manufacturing.

Key figure; main force; important member

Now the fastest growing brand of home engraving machines is xTool, whose sales have tripled within a year, and the market share of home laser engraving machines is very high, the most important of which is the xTool D1 Pro model. And it is constantly updating and iterating to create better home laser engraving machines for all users.

Major Development

HTPOW also began to enter the market of laser engraving machines and 3d printers in June 2022. The purpose is to bring customers the best DIY tools, so that everyone can exert their talents, realize their own creativity, and bring a Station laser engraver experience and service

Key Developments and Consolidations of the Laser Engraving Machine Market

In November 2019, FOBA released a new line-integrated marking solution. Next-generation marking lasers improve line compatibility, installation and use, and maintainability.

In May 2018, TRUMPF invested in its Chinese subsidiary JFY and its Chinese branch TRUMPF China to expand production capacity and capacity.