According to a 2017 study by Grand View Research, the global laser cutting industry will reach $6.72 billion in revenue by 2024. Part of this growth is due to the increasing use of CO2, fiber and diode lasers for marking and cutting in consumer electronics and industrial sectors, leading to increasing demand for such systems.

According to the report, the consumer electronics industry is growing the fastest due to increasing processing requirements for materials that require laser engraving and cutting. In the end-user market, traditional cutting techniques are also increasingly being replaced by laser cutting. As technology advances, many manufacturers can gain a competitive advantage by using laser cutting machines.

James, Director of Marketing at Sculpfun, discusses the industry, market outlook, trends and factors driving growth in the following interview.

1. What Factors Should Manufacturers Consider When Choosing a Laser Engraving Machine?

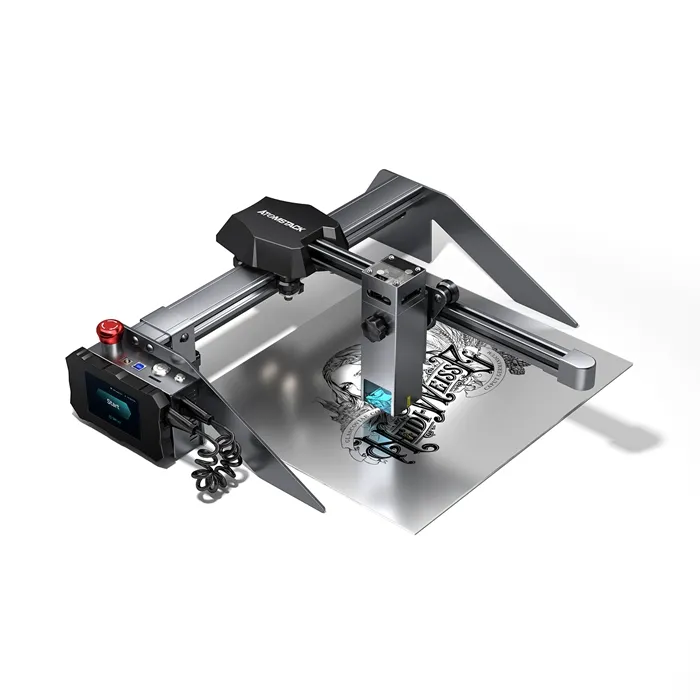

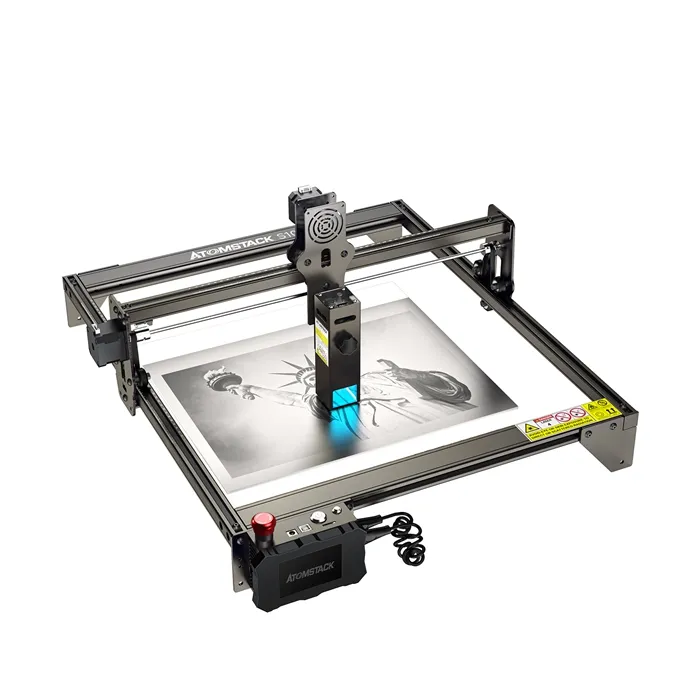

Manufacturers looking for a laser engraver should first clarify a few questions. My first question is what material to work with. This is very important in deciding whether a CO2 or diode laser is required. The next thing to clarify is the maximum size of the material that should fit the device. This helps determine which models or systems are appropriate. The space available at the installation site must also be considered. Once the laser source and model are sized, the required wattage needs to be determined. (The Sculpfun S10 is 10W) For this, you should know the maximum thickness of the material to be cut and the number of products to be processed per day. Other factors may arise later, but these basic questions are a good starting point.

2. Which Industry Is Seeing The Fastest Growth In Laser Engraving? Where Are The Highest Sales?

As for the fastest growing segment, we saw the largest increase in educational institutions receiving lasers. It's an ideal tool for students in a variety of disciplines, from engineering to architecture to arts and STEM subjects. Many universities are also setting up large makerspaces, which are also attractive to recruiters.

On the manufacturer side, we saw the largest increase in the use of lasers for quality control and marking, tracking and monitoring. Laser engraving can engrave serial numbers, time stamps, part numbers and component labels, etch barcodes, mark with DataMatrix codes, branding and industry specific coding. The Sculpfun S30 Pro Max laser engraver produces very high quality marks that can be easily read by barcode scanners, RFID scanners or other inventory tracking devices.

3. What Do You Think Is The Development Trend Of Laser Cutting/Marking Equipment?

HTPOW has been making exciting progress, but the area we're most focused on right now is the user interface. We are trying to make the whole process from design to finished product as simple as possible for users.

4. Do You See a Trend Of Interest In Purchasing Laser Engravers And Laser Engraving In General?

Interest in the B2B and B2C space is clearly growing. The end user sees a fantastic technology that is very versatile. They immediately toyed with the idea of starting a laser engraving business. In the B2B space, manufacturers come to us with specific applications in mind. Then, once the system is delivered and used in these applications, they realize they can use the device for all sorts of other things in the business — custom signage, employee rewards, personalized promotional items, and more.

5. What Feedback Do Customers Who Buy Laser Marking Machines For The First Time Have?

I can't tell you how many times I've heard comments like "I wish I bought a higher powered device" or "I wish I had a bigger table". When purchasing a laser for the first time, it is always difficult to determine the size and power that is right for your needs. Often, they would opt for more space, which still makes a difference. "I wish I bought a smaller laser" is something we've never heard before. But wattage affects throughput. The higher wattage machine can mark a table full of parts faster than a lower wattage (Sculpfun S9 5 W) system. It is important to pair the right sized system with the most efficient power.

6. Which Industry Do You Think Is Just Beginning To Embrace The Benefits Of Laser Marking?

This is a tricky question because there are so many different industries. I think this has to be an industry that already uses lasers, but companies are now finding other uses for them. Many companies have outsourced signage and labeling work and are now realizing how cheap they can do it in-house. It is now increasingly clear to many that the price of lasers has come down during this period and that they can afford their own equipment at the company. This gives companies more control over processes and turnaround times, and is less expensive than their previous outsourcing options.

7. What Improvements Are Needed To Increase The Use Of Laser Cutters/Engravers In Manufacturing?

The most pressing needs of manufacturers are automation and table size. Epilog's largest system measures 40 x x 28 inches - which is impressive. However, large parts manufacturers may require larger equipment to produce their products. Also, laser engraving/cutting systems are not yet automated, which means you need staff to load materials into the system and schedule work. However, ease of use and high-quality labels make up for what some manufacturers may still be missing. Besides, who knows what the future holds for Epilog.

8. In Your Opinion, What Are The Advantages Of Epilog Engravers Compared To Laser Engravers From Other Manufacturers?

The laser market has never been more competitive than it is today. So we're going to focus on a few things that set us apart from the competition. The first is engraving quality, which has always been important to us. With our system, you can always get the best image quality even at the highest speeds. Check out the samples in our Aztec calendar: we can sculpt this incredibly detailed image at a very small size using our standard lenses, even at 100% speed.

The high quality components we use and the speed at which the laser tube triggers are the basis for high quality engraving. Some of our employees have been at Epilog for 15, 20, or even 25 years because they feel connected to the company and take great pride in the systems we build. From the production line to the technical support department to the sales team, everyone wants to provide the best possible product to make our customers successful.