Laser cutting machines focus the laser. It is emitted from the laser into a high power density laser beam through an optical path system. The laser beam irradiates the workpiece surface. It is then brought to the melting or boiling point. So how should we choose the correct power of the laser engraving machine?

Laser cutting is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision and fast cutting speed. Not limited to cutting patterns, automatic typesetting, material saving, smooth cutting, and low processing costs. It will be gradually improved or replaced. Traditional metal cutting equipment.

The 3 Main Types Of Laser Cutting Machines are as Follows

CO2 Laser Cutting Machine

CO2 laser cutters consist of a mixture of CO2 gas and other gases such as helium and nitrogen. This type of gas mixture is charged by discharge, which then generates a laser beam. The wavelength of this tool is 10.6mm.

CO2 laser cutters are the most common and reputable because they are efficient and inexpensive.

Cutting materials: glass, plastic, leather, wood and acrylic.

Crystal Laser Cutting Machine

A crystal laser cutter produces a beam from neodymium-doped yttrium orthovanadate. Compared to CO2 laser cutters, these cutters have a smaller wavelength, so they can cut some thicker materials.

Smaller wavelengths also contribute to better focusing and higher intensity. One disadvantage of these tools is that their parts wear out due to the high power function.

Materials: plastic, metal and ceramic.

Fiber Laser Cutting Machine

The origin of the fiber laser is the seed laser, which uses a special fiber to amplify the power of the laser. A more common name for a fiber laser cutter is a solid state laser.

Significant advantages of this laser cutter include cutting reflective and conductive metals with three times the efficiency of CO2 laser cutters and no moving parts.

Fiber lasers can work on metals and organic materials. Although fiber laser cutters are very similar to crystal lasers, they are more efficient and less expensive to maintain.

So, How to Choose The Right Laser Cutting Machine Power in Actual Needs?

1. First select according to the material to be processed and the thickness of the cut:

We choose the power according to the actual processing material and actual cutting thickness. so that we can determine which model to buy. Such as machine power, working area, etc., is a simple foreshadowing of later procurement work. The application field of laser cutting machine involves many industries. Such as metal processing, advertising, technology, medical equipment, etc.

2. Secondly, choose according to the smoothness of the cutting surface:

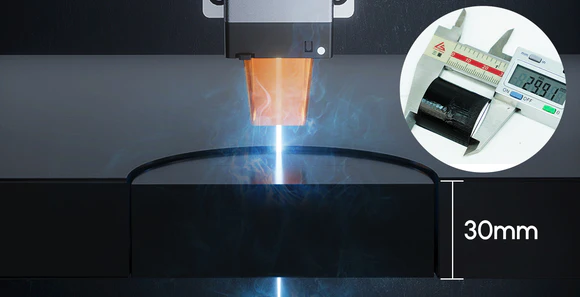

Whether there are burrs on the laser cutting surface is mainly related to the cutting thickness and the gas used. No burr for cutting below 3mm. Nitrogen is the best gas, followed by oxygen and air the worst. The metal laser cutting machine has minimal or no burrs, the cutting surface is very smooth, the speed is relatively high, and the material deformation is relatively small.

3. Three, the choice of laser cutting core components:

Lasers generally use more IPGs, and Raycus is also used. At the same time, pay attention to other parts of laser cutting, such as whether the motor is an imported servo motor, guide rail, bed, etc., because they affect the cutting accuracy of the machine to a certain extent.

4. Four, power selection:

For example, most factories cut sheet metal under 6mm, so there is no need to buy a high-powered laser cutter. But if you are just a home laser cutting machine, you only have 5w, 10w, 20w and other options. A 5W laser cutting machine can meet the marking needs. And the engraving speed is very fast. For example, the engraving speed of LaserPecker 2 can reach 36000mm/min. If the engraving needs are relatively large, then you can choose a 10w laser cutting machine. Because the engraving speed is also related to the laser power, the higher the laser power, the faster the relative engraving speed. The best choice is to buy a high-power laser cutting machine. If you have the need for laser cutting function, then I recommend using a laser engraving machine with a power of more than 20W, because more than 20W can have a better effect on cutting. This type of machine is now loved by everyone, such as xTool D1 Pro, Ortur Laser Master 3, Atomstack S20 Pro, etc., which can greatly improve your engraving and cutting efficiency.

A laser engraver is basically any type of machine that uses a laser to physically remove or cut material to create designs and patterns. The laser beams used in such machines can melt, burn or vaporize materials.

Laser cutting is a manufacturing process. It consists of a very thin, invisible but focused laser beam that cuts and engraves substrates. It can be used both for cutting materials and for creating logos, patterns, designs, and writing text or numbers.

The latter information was made using the engraving option of a laser cutter. Lasers are great for working on metal, wood, glass, ceramics, paper and stone. While other cutting machines rely strictly on one substrate, lasers have a wide range of applications.