What is Glass Engraving?

A laser is a device that generates a light beam through optical amplification. Today, lasers play a significant role in the products we use on a daily basis, from DVD players to barcode scanners.

Lasers are used in manufacturing to cut, sculpt, and drill holes in a variety of materials. Still, they used a technique of drilling holes and cutting away the waste material that was around the laser beam, and then filling those holes. For instance, laser engraving and etching in the manufacture of glass offer numerous options for customization without modifying the properties of the glass.Laser Glass Engraving machines are machines that use laser technology to mark glass materials. There are various methods currently in use in the industry that make use of laser engraver to mark glass and glass materials. One of these applications is used to produce customized glassware.

Laser engraving, cuts a portion of the material, leaving a cavity that displays the design, and the carved part is evident by sight and touch. Laser engraving is performed using a high temperature laser that evaporates the material. In harder materials, the engraving depth usually varies between 0.02 "and 0.125".

Laser etching, on the other hand, does not cut into the material, but uses a less powerful machine to remove only the top layer. The depth of the "cut" is usually no more than 0.001 inches.

The main difference between laser engraving and laser etching is that in the former, a piece of the material is destroyed completely, while in the latter there are only traces of it left on the surface

In the following sections, we'll take a closer look at both, including how they work, their benefits, and how they are performed.

How Does Engraving Work?

In short, a high-temperature laser beam vaporizes the material and physically cuts in, leaving a cavity. In the case of glass, this is due to its internal composition.

Glass is made by heating silicon, which melts at high temperatures and turns into a thick liquid. The molten material is then manipulated in various ways to trap air and water.

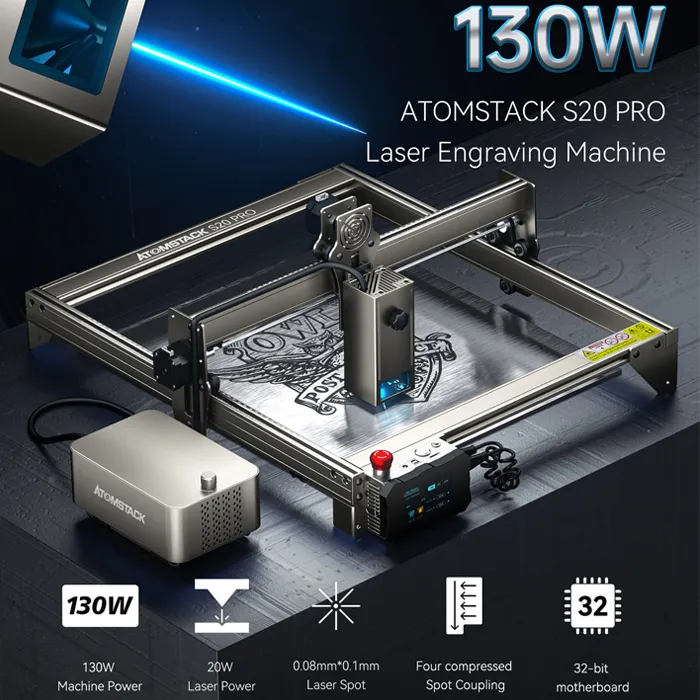

Every time a laser beam hits the glass, the air and moisture react between the silica and the metal element, but not other glass elements like silicon. Specifically, they expand, and since glass is rigid, this can cause microscopic breaks on the surface of the material. What we see and feel is the resulting breakage and fragmentation.atomstack s20 pro and atomstack a10 pro are popular laser engraver of Atomstack,they can directly engrave mirror stainless steel metal, ceramics, glass, and engraving &The cutting speed is 40% higher than the ordinary model, which can be comparable to the effect of the 150W CO₂laser engraving machine.

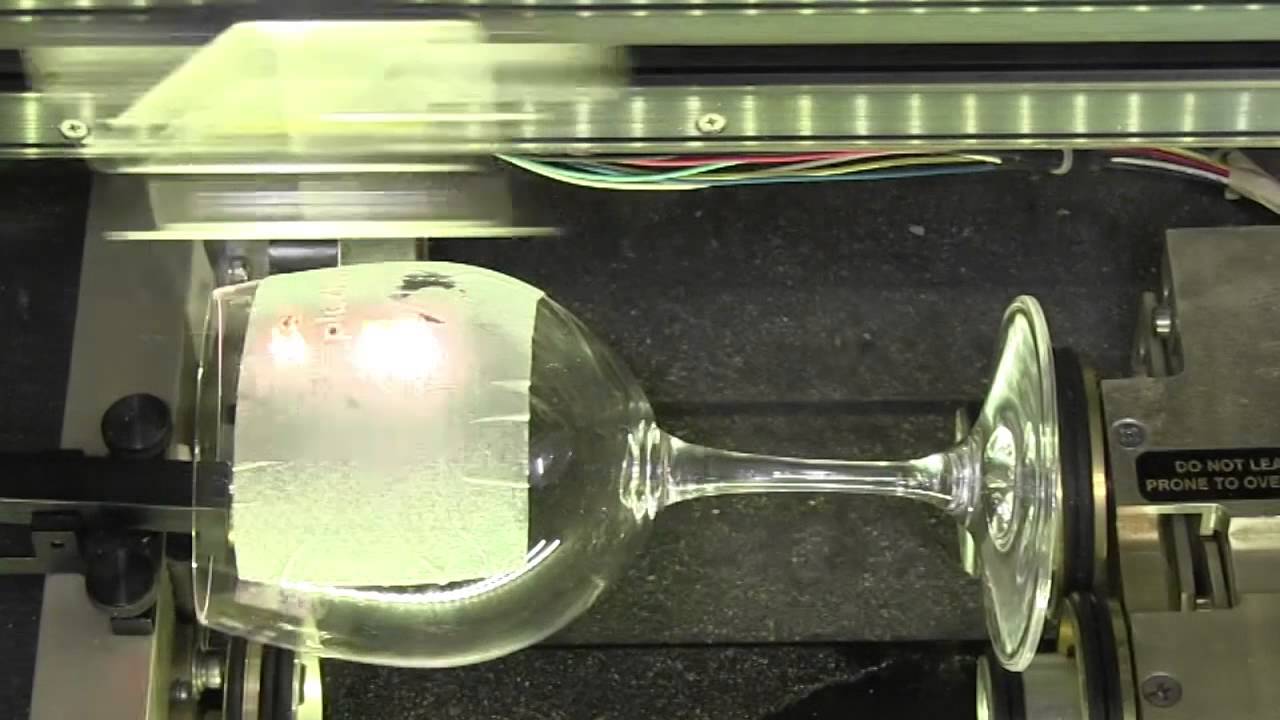

Engraving Curved Glass

When sculpting a surface, the laser may start to lose focus on the side of the figure as the surface begins to bend. Generally, each side has about a quarter of an inch of fault tolerance, but once the beam goes beyond that, your image will start to fade as the laser goes out of focus.

For items with distinct curves or cylindrical products (such as wine glasses), it is ideal to use a rotating attachment that allows the laser beam to be fired as the item rotates.

Cleanliness and Order

While sculpting glass entails crushing and shredding the material, the objective is to make a design with as few splits as feasible. Most carvers will lay moist wipes or newspaper on the glass for this purpose.

After engraving, cleaning is always be required. If there are splinters, use rubbing alcohol and a paper towel or nail brush to remove them. Another alternative for processing is to utilize application tape.

How Does Etching Work?

Laser etching is a subset of engraving that operates similarly to engraving except that the cut depth is generally limited to 0.001 inch. This just alters the surface's appearance, influencing qualities such as reflexes. Laser etching, which is great for thin materials or jewelry, is frequently regarded the best option between laser marking and laser engraving.

Two Machines in One

Laser engraving machines are technically laser etchers, with the only variation being the strength of the laser beam.

Laser engraving and etching are done at different frequencies (the wavelength of light emitted by the laser), which impacts how the laser interacts with various materials. If the etching is done correctly, it gives a lovely, delicate effect since the laser does not harm the substance but instead leaves a frosted appearance when it shines on the glass.

Benefits of Glass Laser Engraving & Etching

Sandblasting and mechanical engraving are both inferior to laser engraving and etching due to a number of factors:

Lasers give your designs the highest level of detail and precision. Even the most intricate images can be carved with extreme accuracy. Additionally, this enables the creation of extremely intricate patterns.

Designs are saved as files so that they can be duplicated with the same level of quality. Non-contact marking eliminates the need to clamp the glass panel, which lowers the risk of breakage.

The cost of laser engraving and etching is relatively low, and fewer tools are needed (such as drills and cutters).

Laser engraving is more adaptable and simple to use than mechanical engraving or sandblasting.

Suitable Glass Types For Glass Laser Engraving & Etching

Here is a list of the ideal glass types that you can use for getting the best results with laser engraving machines:

- Mirror

- Windows

- Cast glass

- Float glass

- Bottle Glass

- Crystal Glass

- Tabletop glasses

.jpg)