When you are looking to buy a diode laser engraver, there are many points to consider. One of the main attributes that differentiate systems on the market is the type of laser tube that the machine uses as the laser source. The two main options you'll come across are water-cooled glass tubes and air-cooled metal tubes. The Ortur Laser Master 3 machine is equipped with metal tubes. Our tubes are also made with high quality ceramic components. Let's take a look at glass and metal laser tubes, and why HTPOW thinks metal tubes are a better choice.

Water-cooled glass tubes are often an attractive option, mainly because of their lower cost. The glass tubes themselves are relatively inexpensive, and their lasers are produced by exciting the gas with direct current (DC), a relatively inexpensive process. The glass tube also produces a high-quality beam that is ideal for laser cutting. However, glass laser tubes have many disadvantages.

Almost all glass tubes require water cooling. Glass is a poor conductor of heat, which means circulating water is needed to help dissipate heat. Without a water cooling system, the glass laser tube will overheat and fail to work. Such a cooling system increases your cost and floor space, and also introduces more points of failure for maintenance.

The need for water-cooling systems also presents some major safety concerns. The DC power supply that excites the diode gas in the glass laser tube needs to operate at a very high voltage. When you combine voltage levels like this with a water cooling system, if something goes wrong, the results can be fatal.

The DC excitation process inherently limits the rate at which the laser tube can be pulsed. When laser engraving, it does not fire continuously. Instead, it "pulses" as it travels through the material, firing many times per second. The pulse frequency of the DC excitation laser tube is low, which will significantly reduce the engraving speed and reduce the engraving quality.

There are also concerns about the lifetime of the DC excitation glass tube. Glass is inherently more fragile than metal and is at greater risk of damage during shipping and installation. The biggest failure problem with glass tubes is that the DC excitation process bombards the tube optics and electrodes with ions, which increases the likelihood of degradation over time. Most glass tubes only come with a 6-month warranty, and if a glass laser tube fails outside of that period, you will often need to buy a whole new laser tube, adding cost and waste.

The only disadvantage of metal laser tubes is their higher cost. For that money, though, you get peace of mind when it comes to performance, durability, safety, and size.

Ortur's metal and diode laser tubes are air cooled and their gas excited by radio frequency alternating current (RF). All that is needed to properly regulate the temperature is the fan built directly into our machine. Not only does this reduce your space footprint, it also eliminates the need (and cost) for additional equipment and limits the number of items that require maintenance. In addition, it avoids the safety problems caused by high-pressure water cooling.

The laser excitation process allows for faster laser pulses, resulting in higher engraving speeds and finer details in the final engraving. Metal pipes are also more durable and last longer than glass alternatives.

At HTPOW we choose to use air cooled metal and ceramic diode laser tubes to build our machines to ensure our customers get the best performing systems possible. All of our tubes come with a two-year warranty, ensuring minimal hassle in the rare event that they cause you inconvenience. In rare cases, our metal laser tubes can often be repaired rather than replaced.

With glass laser tubes, you can achieve high-quality laser cutting at a low price. With metal laser tubes, you can achieve the highest quality laser cutting and laser engraving at the same time, with the confidence that your laser will last longer, engrave faster and be safer.

Every situation and budget is unique, and it is important to research which laser machine and which laser tube is best for you and your business. We believe that investing in an air-cooled metal laser tube will set you up for long-term success.

When you are looking to buy a diode laser engraver, there are many points to consider. One of the main attributes that differentiate systems on the market is the type of laser tube that the machine uses as the laser source. The two main options you'll come across are water-cooled glass tubes and air-cooled metal tubes. The Ortur Laser Master 3 machine is equipped with metal tubes. Our tubes are also made with high quality ceramic components. Let's take a look at glass and metal laser tubes, and why HTPOW thinks metal tubes are a better choice.

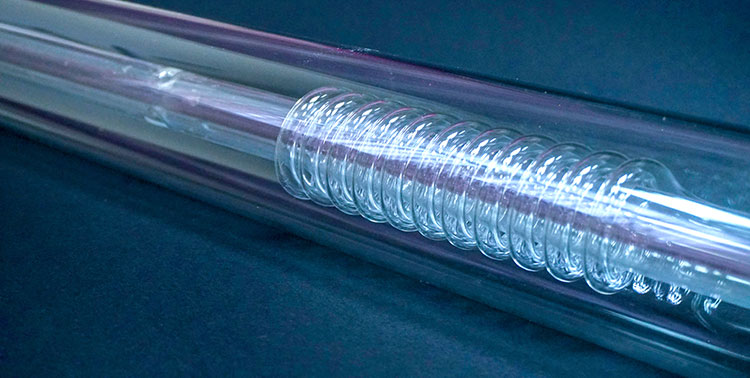

glass laser tube

Water-cooled glass tubes are often an attractive option, mainly because of their lower cost. The glass tubes themselves are relatively inexpensive, and their lasers are produced by exciting the gas with direct current (DC), a relatively inexpensive process. The glass tube also produces a high-quality beam that is ideal for laser cutting. However, glass laser tubes have many disadvantages.

Almost all glass tubes require water cooling. Glass is a poor conductor of heat, which means circulating water is needed to help dissipate heat. Without a water cooling system, the glass laser tube will overheat and fail to work. Such a cooling system increases your cost and floor space, and also introduces more points of failure for maintenance.

The need for water-cooling systems also presents some major safety concerns. The DC power supply that excites the diode gas in the glass laser tube needs to operate at a very high voltage. When you combine voltage levels like this with a water cooling system, if something goes wrong, the results can be fatal.

The DC excitation process inherently limits the rate at which the laser tube can be pulsed. When laser engraving, it does not fire continuously. Instead, it "pulses" as it travels through the material, firing many times per second. The pulse frequency of the DC excitation laser tube is low, which will significantly reduce the engraving speed and reduce the engraving quality.

There are also concerns about the lifetime of the DC excitation glass tube. Glass is inherently more fragile than metal and is at greater risk of damage during shipping and installation. The biggest failure problem with glass tubes is that the DC excitation process bombards the tube optics and electrodes with ions, which increases the likelihood of degradation over time. Most glass tubes only come with a 6-month warranty, and if a glass laser tube fails outside of that period, you will often need to buy a whole new laser tube, adding cost and waste.

The only disadvantage of metal laser tubes is their higher cost. For that money, though, you get peace of mind when it comes to performance, durability, safety, and size.

Ortur's metal and diode laser tubes are air cooled and their gas excited by radio frequency alternating current (RF). All that is needed to properly regulate the temperature is the fan built directly into our machine. Not only does this reduce your space footprint, it also eliminates the need (and cost) for additional equipment and limits the number of items that require maintenance. In addition, it avoids the safety problems caused by high-pressure water cooling.

The laser excitation process allows for faster laser pulses, resulting in higher engraving speeds and finer details in the final engraving. Metal pipes are also more durable and last longer than glass alternatives.

At HTPOW we choose to use air cooled metal and ceramic diode laser tubes to build our machines to ensure our customers get the best performing systems possible. All of our tubes come with a two-year warranty, ensuring minimal hassle in the rare event that they cause you inconvenience. In rare cases, our metal laser tubes can often be repaired rather than replaced.

With glass laser tubes, you can achieve high-quality laser cutting at a low price. With metal laser tubes, you can achieve the highest quality laser cutting and laser engraving at the same time, with the confidence that your laser will last longer, engrave faster and be safer.

Every situation and budget is unique, and it is important to research which laser machine and which laser tube is best for you and your business. We believe that investing in an air-cooled metal laser tube will set you up for long-term success.

.jpg)