Laser cutting and laser engraving are two processes that use a laser engraving machine. Therefore, they belong to the same class of processes called laser marking methods. It's just that laser markings are not of the same intensity, and since they are in the same category, they can be confused with each other. Therefore, this article aims to discuss the differences and similarities between the two laser methods.

What is Laser Cutting?

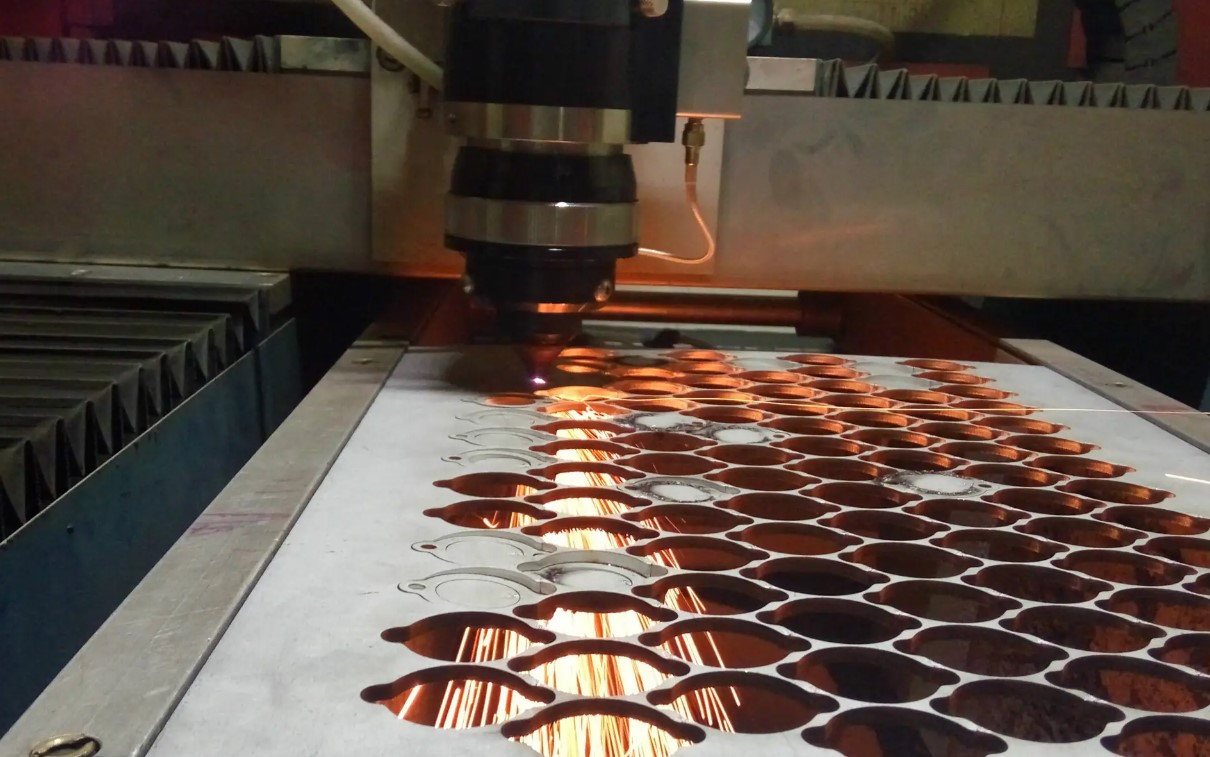

Laser cutting is a process that involves using a focused laser beam to cut different materials. Therefore, it is suitable for creating customizable patterns, shapes and designs on workpieces. Like any other laser marking process, it is non-contact, i.e. the machine does not come into direct contact with the material. However, the laser beam can cut through the material by melting, vaporizing or burning part of the part, creating an empty line. The representative product of laser cutting machine is Ortur Laser Master 3.

Laser cutting works on a variety of materials, including metal, plastic, ceramic, wood, acrylic, and stone.

What is Laser Engraving?

Laser engraving is another laser marking method that involves using a laser beam to engrave pictures and logos on objects in the form of images, barcodes, serial numbers, etc. Laser engraver mark by evaporating the desired portion of an object to leave a permanent deletion. They are compatible with wood, plastic, coated metal and leather. It is recommended to use laserpecker 2 for laser engraving, with an engraving speed of 36000mm/min, to meet all your engraving needs

Difference Between Laser Cutting and Laser Engraving

Both of these processes are laser marking procedures. This is because they use a laser marker to create a beam of light that can evaporate some or all of the product. While similar, here are some differences between laser cutting and laser engraving:

· Cutting Principle

Laser cutting involves the use of a laser beam to cut through the entire thickness of a material by melting, burning and evaporating. Most cuts are perfect. Therefore, they do not need a second touch-up. Laser engraving, on the other hand, involves cutting to the desired depth without cutting the entire thickness. As a result, the engraving material evaporates its surface only to the required depth.

· Laser Power

One of the most important differences between laser cutting and laser engraving processes is based on the machine used. Here, the laser power is a definite parameter. On the one hand, a laser cutting machine is a machine with a laser power of more than 10W. High power is important for cutting, although it depends on the type and thickness of the material.

Differences in laser power also limit the types of laser machines that are compatible with the process. For example, most laser cutters are fiber or CO2 laser markers. However, laser engravers may include other laser markers, such as UV or green lasers.

Laser engraving machines can cut non-metallic flakes.

· Lens Focal Length

Another important difference when comparing the two processes is the focusing lens used in the laser machine. Laser cutters have lenses with long focal lengths. Therefore, they offer smooth cutting edges that make them aesthetically pleasing. On the other hand, the lens focal length of a laser engraver is shorter. As a result, they provide objects with a finer spot size, which improves engraving quality.

· Cutting speed

Typically, the laser cutting process is very slow due to the time and energy required to fully vaporize the material. However, it depends on the material you are cutting and its size. For example, thin metal will take less time than thick metal, and thin plastic will take less time than thin metal. In addition, the slow cutting speed ensures a smooth and high-quality front end.

Laser engraving has a higher cutting speed because the process does not involve cutting. In addition to this, it helps to increase efficiency and reduce contact time. However, cutting too fast can result in poor marking quality. Cutting speed and laser power are related, and the higher the power, the finer the engraving can be.

· Use of Auxiliary Gas

Assist gases such as helium and oxygen help expel the molten material seen during laser cutting. Therefore, they are highly recommended for cutting thick materials. In addition to expelling molten material, they also cut a smooth appearance.

Laser engraving, on the other hand, does not require assist gas because it creates a popping sound that affects the appearance of the surface finish. However, you can use it when the engraving process produces too much smoke, as the gas prevents the smoke from affecting the marking quality.

Get the Best Laser Cutting and Engraving Machines

Laser cutting vs laser engraving is a common comparison in laser marking. However, the two processes are different, and understanding what they mean can help you make the right choice. This article describes the two processes and their differences.

Are you looking for a laser marking machine for cutting or engraving? You can find the laser engraving and cutting machine you need in the HTPOW online store