With the development of laser engraving machine, more and more people like to use laser engraver for customized design, because it not only makes your items look personalized, but also makes your items not easy to lose and easy to find. htpow through many surveys and research, found that there are 5 engraving materials are liked by everyone. And many laser engraving machine manufacturers are doing a good job of updating their engraving machine products to make laser engraving machines easier for most people to use

Let'S Take A Look At The 5 Carving Materials

Wood

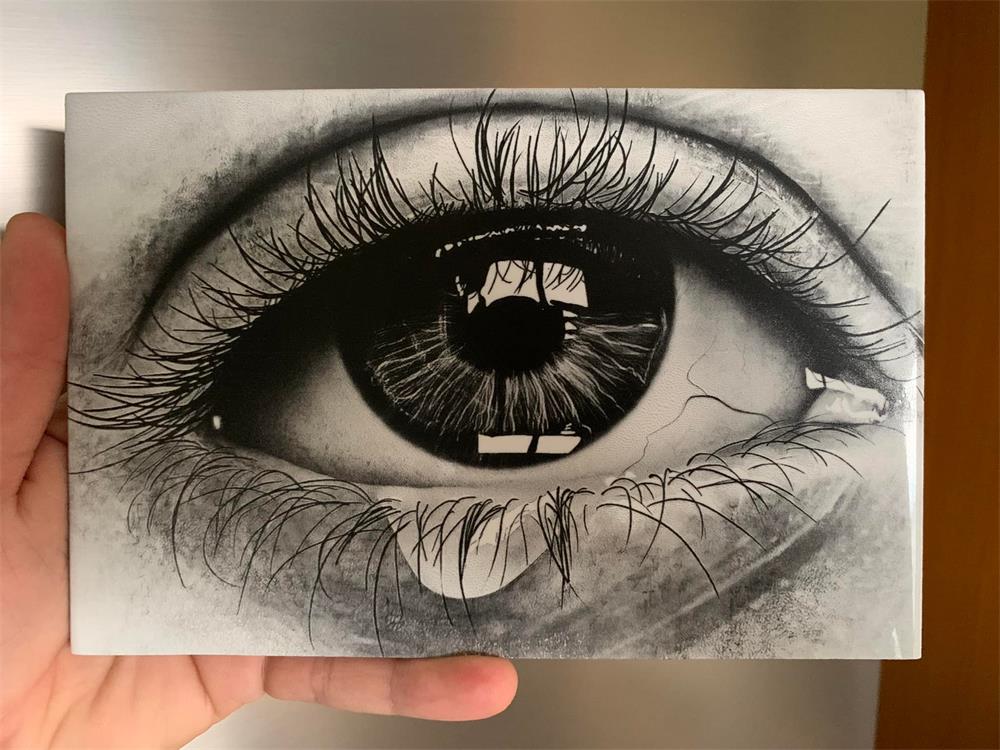

Logs are the most commonly processed material for laser engraving machines and are easy to engrave and cut. Cherry and maple are the best woods. HTPOW has done tests because these two woods have a more uniform density. So the engraving pattern is very symmetrical and very good for engraving, especially 3D engraving. Of course, maple carving will give better photos because maple is white. And the contrast of carving is more in line with our aesthetic standards. On the other hand, maple is red, but the difference in carving is also significant.

Plywood is a type of board that is extruded with wood chips and glue. So the edges of plywood, when cut, will be blackened like wood. The key depends on the quality of the cement and wood chips used in plywood. Poor quality blackening will be particularly severe. So we don't recommend using plywood for laser engraving and it will produce a very bad smell due to the laser burning.

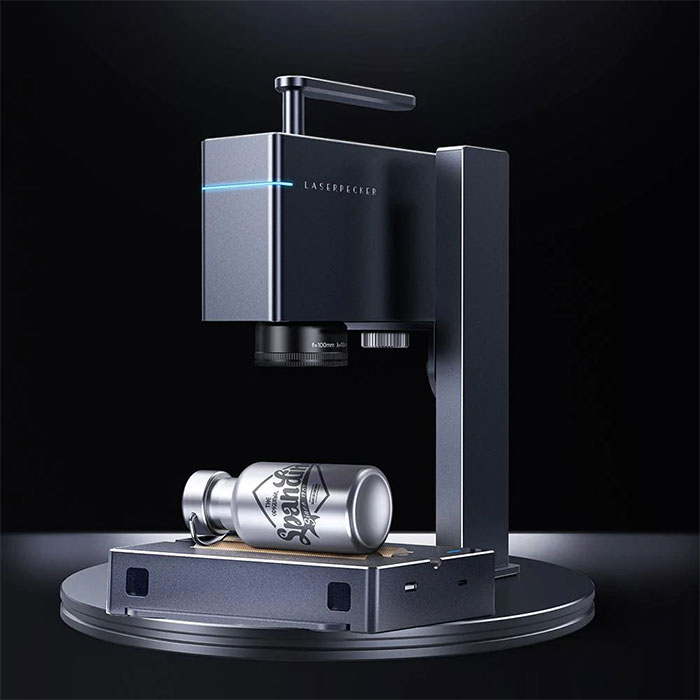

In our engraving with Ortur Laser Master 3, we usually use birch and basswood plywood. Wood carving generally uses wood with little texture and uniform timber, so that the carving is fine and delicate enough. Of course, contrast is also essential. If you want to carve deeper, you can slow down and increase the power. If you lighten the color, you can increase the carving speed and try cutting more times. Many laser engraving machines like Ortur, xTool, LaserPecker, etc. can be set to wood engraving mode, which also allows for faster laser engraving, when one still needs to adjust the laser intensity and engraving speed, etc., corresponding to the actual wood material.

Because plywood and logs have glue, cutting will produce oil smoke. At this time we need to use a light blowing to avoid blowing the oil smoke onto the board and attaching it to the surface. If you are cutting wood, it is the opposite, you need to intensify the blowing, which can reduce the carbonization of the wood.

Density Board

MDF is very similar to our plywood, but it will be more dense, so generally speaking, density board is more difficult to cut than plywood, and it is easy to blacken when cutting. It is better to buy E0 grade density board. The more smoke produced when carving MDF, the faster it will be. Make sure the suction power of the exhaust fan is sufficient and the smoke needs to be sucked away in time. Otherwise, the lens will be contaminated. When engraving MDF boards and panels, a low DPI for images or artwork is sometimes sufficient. The lower resolution of the image will increase your overall speed and thus reduce the time needed to complete the job.

Acrylic

Acrylic is the most commonly used material for engraving, just like wood. It is easy to cut and engrave. It is widely used in the advertising industry to make advertising fonts. There are two production processes for acrylic: casting and extrusion. Laser engraving is mainly used to produce acrylic by the cast method, because the white effect produced by laser engraving is very uniform and contrasts with the original transparent texture.

The acrylic after extrusion engraving is not white enough and the contrast is not enough. In addition, high purity acrylic should be purchased. Some low purity acrylic cutting will emit an unpleasant odor, and the cutting and carving effect is not good. Acrylic carving is generally carved from the front, viewed from the back, so that the finished product is more three-dimensional.

Reverse cutting needs to be put into the software first to process the pattern, carving speed should be fast and power should be small. If the power is too high when carving, uneven stripes will appear at the bottom. Want to carve deeper, you can try to cut more.

It is well known that acrylic is easy to cut and the cutting edge is smooth. It is recommended to use a wider laser head to reduce the blowing pressure when cutting. If blown too hard, the acrylic edge will be white and the surface will become rough. Note: The operator cannot leave when cutting acrylic, and it may catch fire when cutting, so the blowing air must be turned on when cutting acrylic, and the auxiliary blowing air will reduce the temperature and prevent the fire

Two-color Plate

Two-color plate is a kind of engineering plastic specially used for engraving, made of two or more layers of color composite. Its specifications are generally 600*1200mm. Australian Rowmark quality is stable and abundant. Trotec's two tone color plates are also of good quality. Engraved two-tone plates are usually used for various logos and emblems. Two-color leaves can be divided into two main categories: mechanical and laser plates. Some mechanical plates can also be used for laser engraving. Laser engraved plates are characterized by a thin surface color layer (<0.1mm). Laser plates are generally 1.3mm-0.8mm, and the plating of special laser plates will be resistant to high temperature, and the engraving effect will be better. (Mechanical plate is generally 1.5mm). Our experience is that if the surface color of the plate is leathery, it can generally be laser engraved. If the surface color is thicker, it can be engraved twice.

If laser engraving is done by using laser engraving two-color plate, the effect will be very good, with obvious contrast and precise edge. When using a mechanical scale with a thin surface, the engraving results are similar to those of a laser plate. On closer inspection, the edges may not be as transparent as laser plates because they are not resistant to high temperatures and the edges can melt. The cutting speed of the two-color plate should be relatively slow and should not be cut through at one time. It should be done three or four times so that the edges of the cut out material are flat and without melting marks. The power should be appropriate when engraving, not too large, so as not to melt the waste.

Clean the surface with wet cloth or alcohol after carving. However, it should be noted that if the laser power is set too high when engraving, a layer of dust that is difficult to erase may be attached to the surface of the two-color panel, which can be blown off by using the blowing-assisted version.

Glass Laser Engraving

Laser can engrave on the glass surface, but the engraving depth is not deep enough to cut, and the high laser energy will burst the glass. Usually, the laser will frost or crack the glass surface.

Usually, users want a frosting effect rather than a breaking effect, depending on the texture and hardness of the glass. Engraving of glass is often difficult to control and the following steps can be followed to create a smooth frosted surface: Apply a little soapy water to the area to be engraved and then lay a damp paper towel on the surface.

Place the glass in the engraver and cut while the paper is still wet, then remove the glass, remove any remaining paper and clean the surface. The laser power setting is generally small and the engraving speed is 300mm/s. If the engraving effect is not good, try to scatter focus.