In recent years, laser engraver have been used more and more widely in the processing of handicrafts, whether in the field of metal cutting or non-metal cutting. Facing the numerous laser cutting equipment on the market, how to choose the laser that suits your needs The cutting machine can be considered from the following aspects:

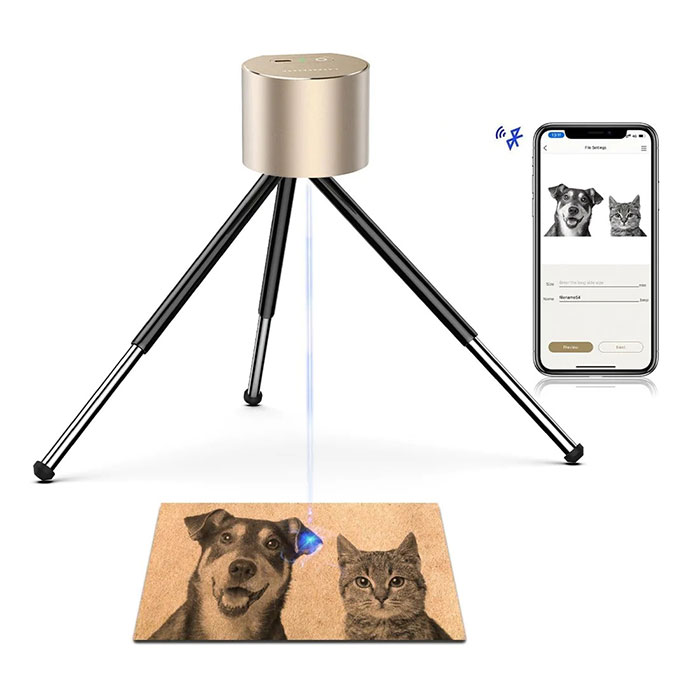

Consider first the materials your business processes. It is generally divided into two types, metal cutting and non-metal cutting, and the machine is selected according to the material to be cut. There is also a kind of mixed cutting, that is, metal and non-metal can be used, but this kind of machine is not recommended, and it is not easy to use. And choose a well-known and reliable brand engraving machine, Ortur can meet the needs of most home engraving machine enthusiasts.

If you are using it for your own home, you can choose the Ortur Laser Master 3 laser engraving machine. The CO2 laser cutting machine is mainly used for cutting non-metallic materials, and the wavelength is around 10600. It is best to use optical fiber or YAG equipment for cutting metal materials, because their wavelength is between 1060 and 1070, and metal materials have energy absorption problems for this wavelength. If it can be cut with CO2 equipment, it will be melted completely by energy.

Three Steps to Teach You How to Choose a Laser Cutting Machine!

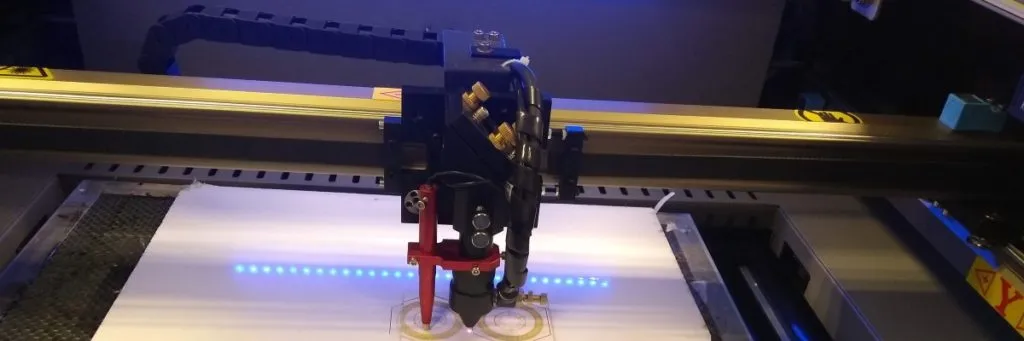

1. For non-metal cutting, the machines are divided into two types with high power and low power according to different application functions. Some low-power cutting machines are only suitable for color plates, architectural models, small signs, and three-dimensional handicraft material processing. This process has been popular for a while, but the power is too small, which will greatly affect its application range. Another kind of high-power spindle cutting machine is divided into two categories, one is large-format cutting machine: the size is generally more than 1 meter, but this is generally poor precision cutting machine, another format is gentle cutting machine: this kind of engraving Machines are generally used in precision machining and organic sign making. In terms of size, choose a laser engraving machine according to your own needs, the size of the object cutting area, and the size of the site. Generally speaking, each manufacturer has different laser cutting machine sizes, like Leiyu Laser, there are four different sizes to meet the needs of different industries. For small DIY workshops, you can choose the small Ortur Laser Master 2 laser cutting machine machine.

2. For metal cutting, if most of the company’s own process requirements are plates below 3mm, and a small amount of 3-6mm plates are used, and the product batch is small and there are many types, then the 500W small and medium power YAG metal laser cutting machine can be purchased. High reflective materials such as copper and aluminum overcome the shortcomings of optical fiber and CO2 laser in cutting high reflective materials. If the enterprise itself mainly processes handicrafts, it is the best choice to purchase a 40w-150W laser cutting and engraving machine. The equipment purchase cost is low, the processing materials are diverse, and the cost performance is high. Therefore, the size of the power cannot be used as the only indicator to evaluate the quality of a laser cutting machine, and the equipment that can properly meet the processing level of the enterprise is a more rational choice.

3. Equipment quality and use stability are also very important indicators. Now the product research and development cycle is short, the replacement is getting faster and faster, product diversity, sample trial production, and mass production are more, how to complete customer orders with quality and quantity, maintain corporate reputation, and enhance corporate competitiveness are also placed on every day. It is a daunting task for an operator, so the purchase of processing equipment with stable performance is the premise and foundation. Try to choose a brand with a high market share, a sound after-sales service system, many after-sales service outlets, and a long-term market test. Buying low-quality and low-quality products without after-sales service will have a huge impact on the production of enterprises. The after-sales service of each manufacturer is very different, and the length of the warranty is also uneven. In terms of after-sales service, the warranty period of Leiyu laser cutting machine is one year. It not only provides customers with effective daily maintenance solutions, but also produces a series of supporting teaching videos for the machine and laser software LaserMaker to help customers get started as soon as possible.

You can easily buy the laser engraving machines mentioned above in the HTPOW online store, and they are also very cost-effective. And HTPOW will also give you very professional help and knowledge.