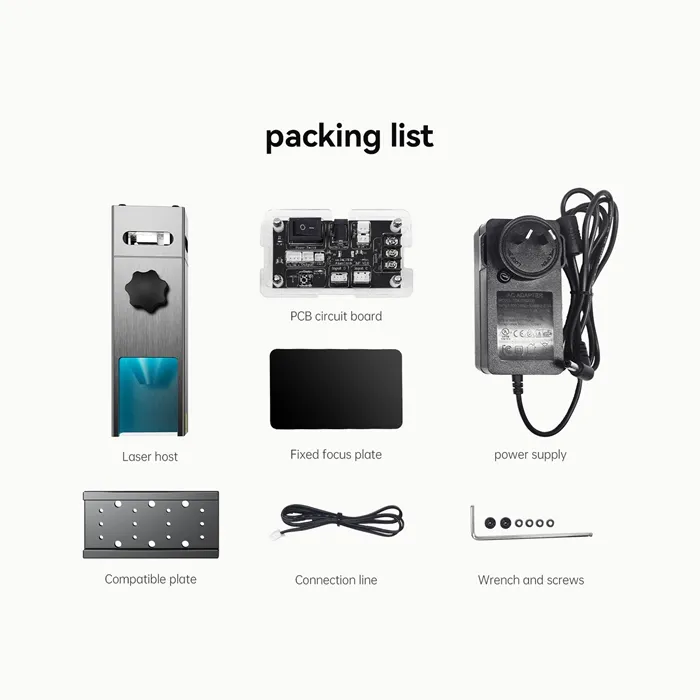

LASER MODULE SPECIFICATION

Product Name: M50

Product Number: M50

Specification Model:44*52*118mm

| Brand | Atomstack |

| Product Material | Aluminum 6061 anode |

| Housing size | 44*52*50 mm |

| Circuit Board Size | 44*52 mm |

| Circuit Board | 12V/PWM modulation board |

| Wire Rod | 22# 2P2.54 terminal reverse wire 80mm |

| Optical Lens | φ6/glass |

| Fan | 12V |

| Laser Beam Mode | Spot |

| Working Mode | Pulse work |

| Lightspot Size | 0.08*0.15mm |

| Working Time | 10000H |

| Working Temperature | 0℃~70℃ |

| Storage Temperature | -40℃~85℃ |

| Sintering temperature | 1000~1200℃ |

| Items | Symbol | Min | Typ | Max | Unit | Condition |

| Optical Output Power | Po | 9.5 | 10 | W | 12V Power | |

| Working current | Iop | / | 2.9 | 3.2 | A | |

| Operating Voltage | Vop | / | 12 | / | V | |

| Laser Wavelength | λp | 455 | 460 | nm | ||

| Electric Power | Wl | / | 34.8 | 38.4 | W |

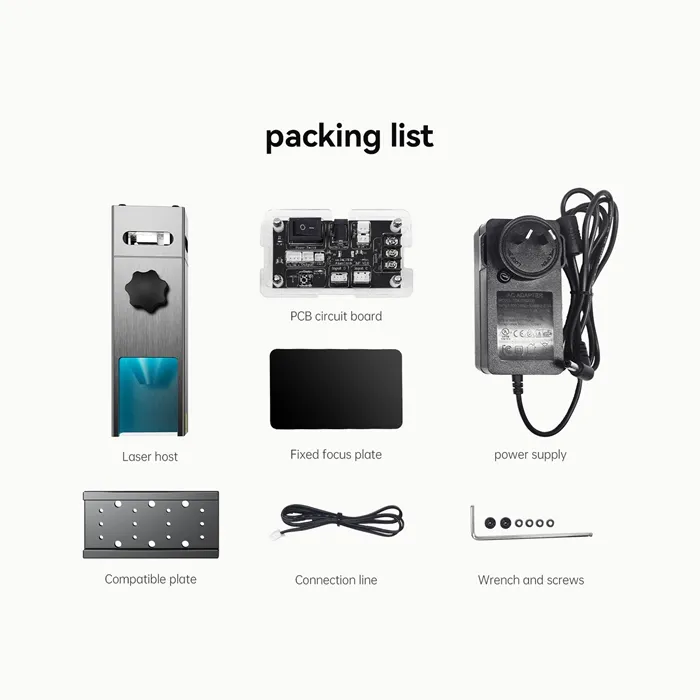

Atomstack M50 50W Laser Module Features:

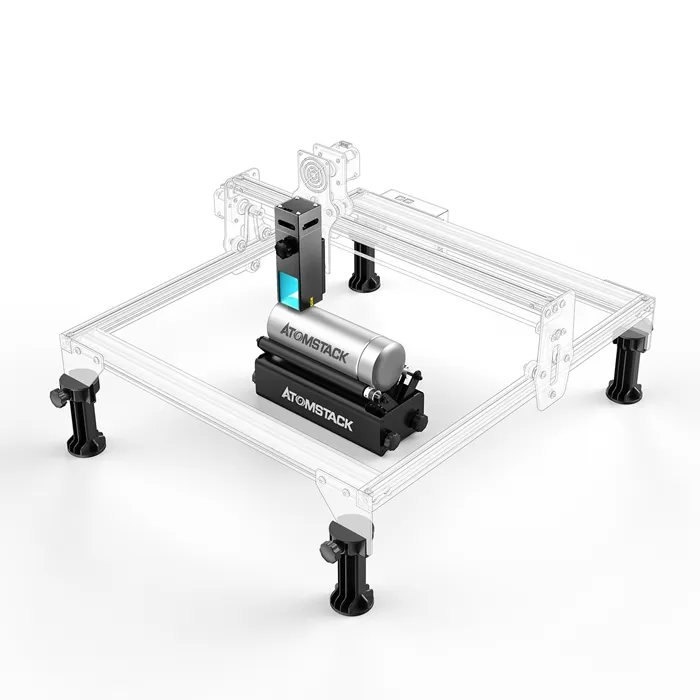

1.It can be used for laser cutting machine, laser engraving machine, CNC, DIY laser.

2.Laser protective cover: The laser is equipped with a protective cover to protect the eyes of the user without the need to wear additional protective glasses. At the same time prevent pets from grabbing the laser spot.

3. Made of aluminum, strong and durable.

4.Upgraded high quality fixed-focus laser, no need to focus.

5. Aviation aluminum TTL driver board with cooling fan can ensure continuous long time work.

6.Engravable materials: wood, bamboo, cardboard, plastic, leather, PCB board, aluminum oxide, non-reflective electroplating layer and lacquered metal, after blackening Utility knife.

7.Cutable material: cardboard, non-woven fabric, veneer, acrylic, some thin plastic board.

8.0.08*0.15mm double compression spot light coupling technology makes engraving more powerful

and precise .

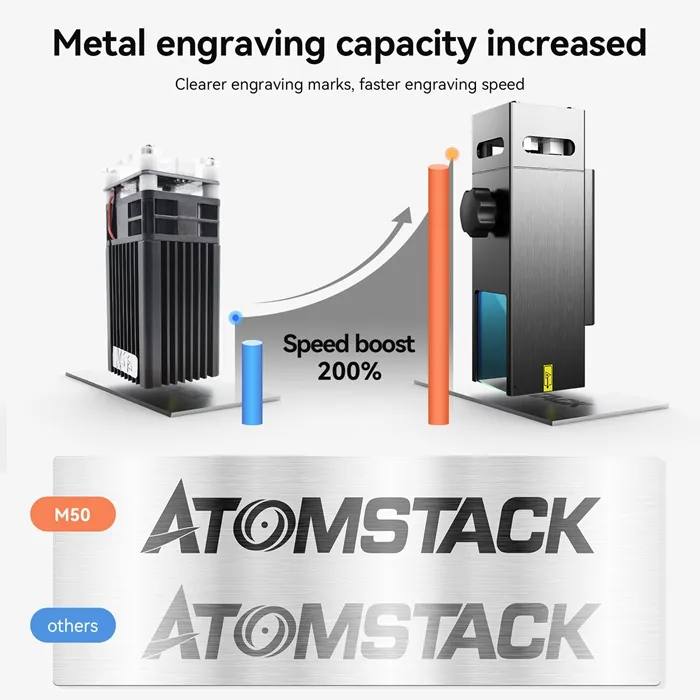

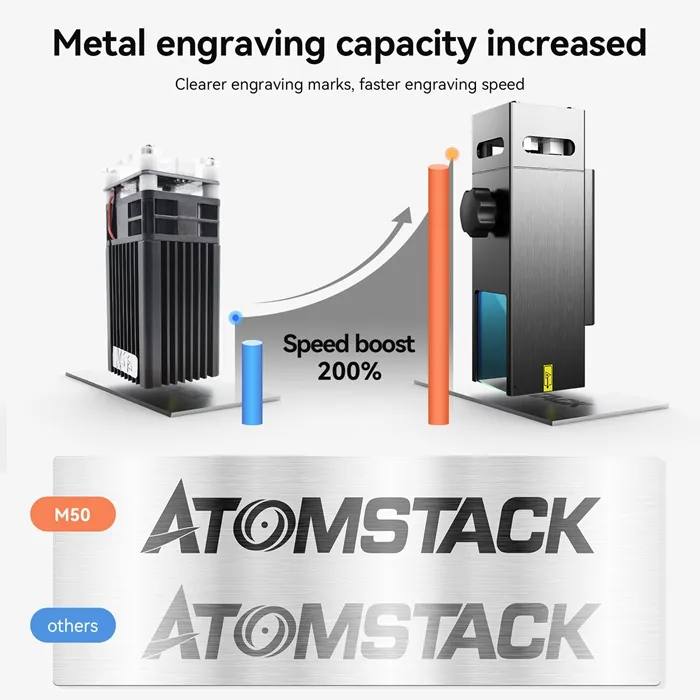

9.Engraving speed is 200% higher than other 5W lasers.

10.High energy can cut 8.5mm thickness plates at one time.

11.The laser sintering temperature is 1100 degrees, the effect of engraving metal is better.

12.The laser has a built-in horizontal gyroscope anti-tip protection device, and it stops working when

the tilt angle is 20°.

13.The wind-collecting hood can clean the smoke and dust to protect the lens to avoid laser

energy attenuation.

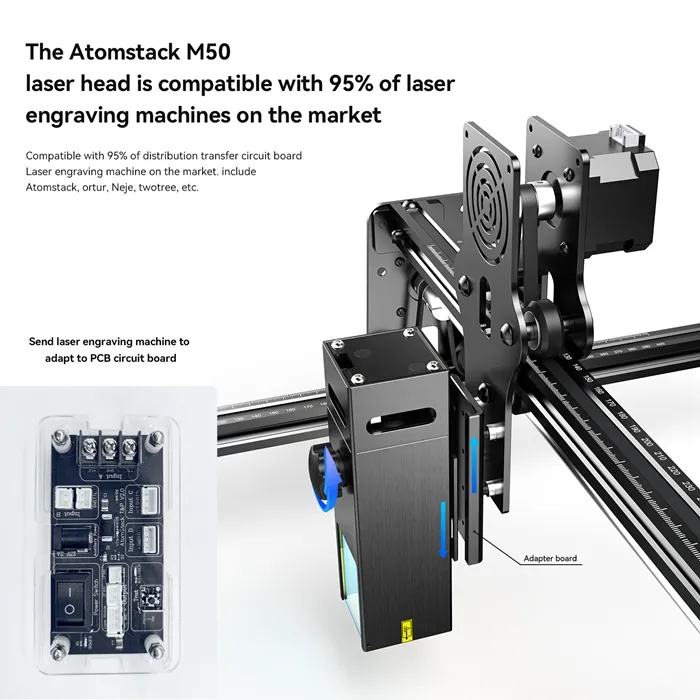

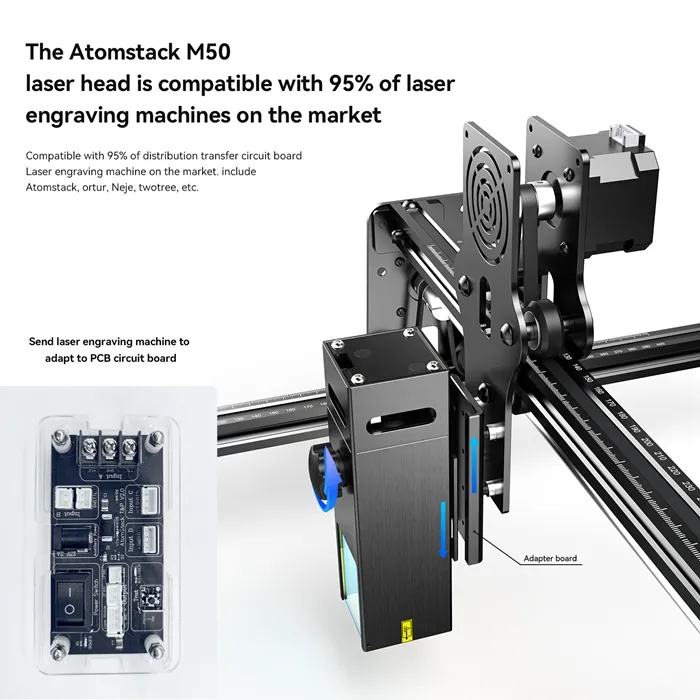

14.The transfer circuit board is compatible with 95% of laser engraving machines on the market,

Including Atomstack, ortur, Neje, twotree, etc.

CAUTIONS

1.The laser light emitted by the laser module is likely to injure persons'eye, so do not

directly gaze its end surface and wear appropriate safety glasses to prevent laser light

when it is working.

2.Laser module needs an appropriate laser driver(PCB). When the laser module connects with

power supply, please set the output voltage to zero. The adjustment of the current should

be slowly increased or decrease to avoid damaging the device.

3.Keep the device working or storing in a dry environment. The anti-dust grade is over one

million, in order to prevent dust inside the lens to affect the laser dot shape.

4.Working at high temperatures will increase the threshold current, reduce conversion

efficiency and speed up the aging of the device.

5.When output power is higher than it's specific parameter of operation, it will accelerate

the aging of the device.

6.When the operation temperature of the laser diode is over 70degree, please do well heat

dissipation of it.

7.This laser module is an electrostatic sensitive device. Please make sure ground yourself

or wear an antistatic wrist strap before you take it.