Compared with the traditional Chinese design and manufacturing development method, 3D printing technology is more suitable for the manufacture of complex objects and personalized customization, and it can save a lot of time and cost. 3D printing modeling is actually the latest rapid prototyping device utilizing technologies such as light curing and paper lamination. 3D scanning is used to manufacture models in the fields of mold manufacturing, industrial design, etc., and is gradually used in the direct manufacturing of some products, which has a profound impact on traditional technological processes, production lines, factory models, and industrial chain combinations. It is a representative disruptive technology of the manufacturing industry. 3D printing is a technology that builds objects by layer-by-layer printing based on digital model files, using adhesive materials such as powdered metal or plastic. This technology was first proposed in the United States in the mid-1980s. At present, this advanced manufacturing method of learning has been widely used in many research fields, such as medical care, education, industry, creative manufacturing, etc. However, there are also some friends who are new to 3D printing and may still be in the conceptual stage. We will unveil the mystery of 3D printing for you and take you to know more. Here are some quick steps to help you start your 3D printing journey:

Here are some quick steps to help you start your 3D printing journey

1. Select consumables

Printers that are bought back usually come with a roll of consumables, the two most popular of

which are PLA and ABS. Of course, it does not mean that only these two materials can be printed.

It mainly depends on which materials the machine can support. It is best to communicate with the

seller before purchasing the machine.

Filaments for 3D printing usually come in two different diameters: 1.75 mm and 3 mm. Apart from the diameter, filaments also come in different spool sizes. Check out our filament guide to learn about the most popular 3D printing filament types. In it, we go over their uses, properties, and where you can buy them.

Filaments for 3D printing usually come in two different diameters: 1.75 mm and 3 mm. Apart from the diameter, filaments also come in different spool sizes. Check out our filament guide to learn about the most popular 3D printing filament types. In it, we go over their uses, properties, and where you can buy them.

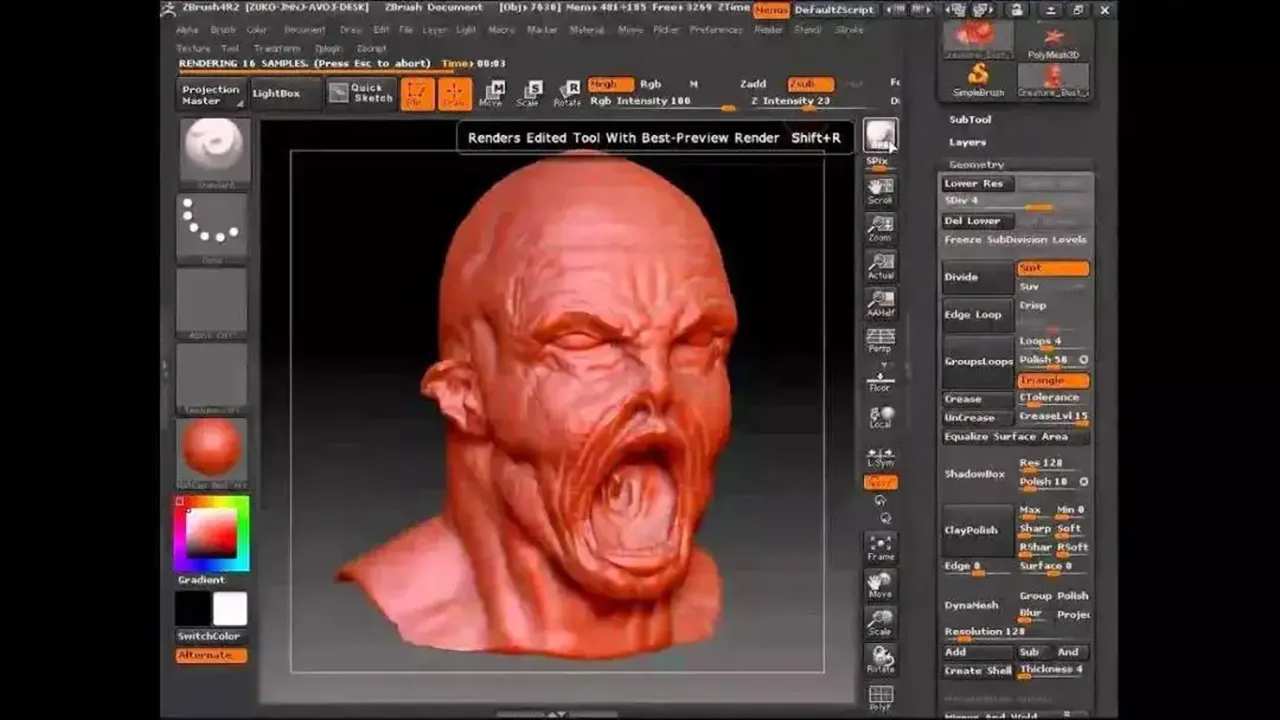

2. Modeling

If you can use modeling software to build a model yourself, that is definitely better. But if

you don't know how to model, it doesn't matter. You can find free models on some websites,

download them and use them. After you have a certain foundation for modeling, you can design

models according to your own personalized needs.

3. Slicing

The slicing software is a software for setting parameters and converting model formats. After

purchasing the machine, it usually comes with it, and it will be placed in a U disk or SD card.

Of course, other slicing software can also be used for slicing. After you have selected the

model, put the file into the slicing software, set some parameters, and then store it in the SD

card. The format of the stored file needs to be gcode. Finally, insert the SD card into the

printer to start printing.

4. Printing

The next step is to turn the digital file into something tangible. Of course, this step involves

the most critical tool: the 3D printer.

A good 3D printer with simple operation and stable quality can help us accurately restore the designed model. However, poor quality 3D printers can suffer from shrinkage distortion, rough surfaces, machine jams, misplaced prints, and more. Therefore, it is very important to choose a good 3D printer.

Currently, there are two types of 3D Printers that are most popular among consumers, FDM and UV Photocuring. While they may seem similar at first glance, there are many differences between FDM and UV Photocuring 3D Printers that make the optimal for different applications.

Fused Deposition Modeling, or FDM is the most popular on the market today. FDM uses thermoplastics (meltable plastic filaments) to create an object layer by layer, starting from the build plate and building the model from the ground up.

A good 3D printer with simple operation and stable quality can help us accurately restore the designed model. However, poor quality 3D printers can suffer from shrinkage distortion, rough surfaces, machine jams, misplaced prints, and more. Therefore, it is very important to choose a good 3D printer.

Currently, there are two types of 3D Printers that are most popular among consumers, FDM and UV Photocuring. While they may seem similar at first glance, there are many differences between FDM and UV Photocuring 3D Printers that make the optimal for different applications.

Fused Deposition Modeling, or FDM is the most popular on the market today. FDM uses thermoplastics (meltable plastic filaments) to create an object layer by layer, starting from the build plate and building the model from the ground up.

What can I do with a 3D Printer?

In daily life, 3D printers are mainly used for personalized customization, unique figures, animation peripherals, 3D portraits, personalized accessories, etc. In short, its existence has indeed made us realize more impossible. He is subtly changing our lives!

Personal Field

In terms of personal use, at present, consumer-grade 3D printers continue to affect the daily work and life of individual players with the advantages of economical benefits, high cost performance, stable operation, and fine printing. Consumer-grade 3D printers have begun to be implanted in the hearts of the people.

Family Field

Using a 3D printer at home can be seen as a scaled-down version of a "mobile micro-factory". When a user loses an item, they can download it through their own design or search for the relevant product model on the Internet, and then print it out. Even vases, hangers, lampshades, toys, etc. at home can be printed with 3D printers. Compared with buying online, hand-made can add a lot of fun to the family atmosphere.

Industrial Field

The rapid creation of concept models through 3D printing enables better communication between designers and clients. In traditional industrial manufacturing, if a design concept is defective after it is made into a product, the company needs to bear the cost of wasting a lot of materials. Using 3D printing technology to make concept models, it is possible to quickly adjust the initial design and continuously improve it.

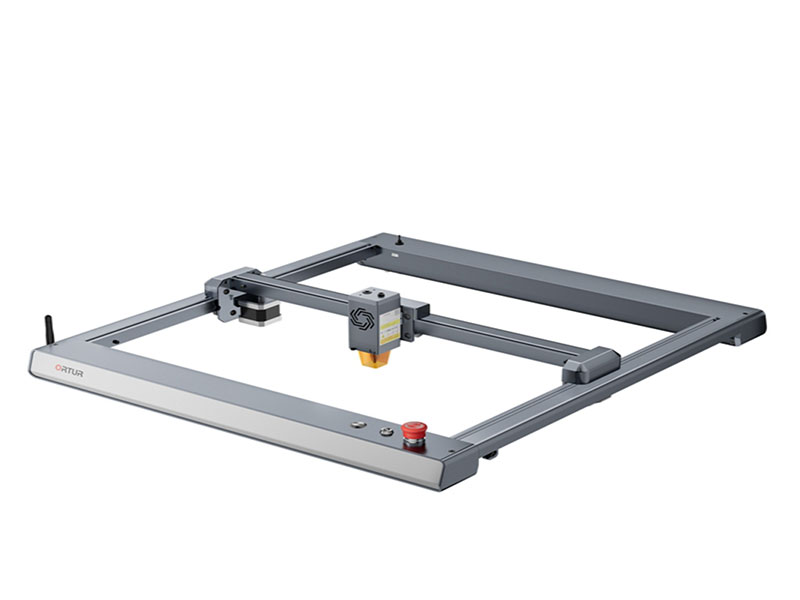

Are laser cutters/engravers worth it?

Laser cutters and engravers are worth it. If you are an artist or professional, you can make your own custom items for your projects. You can make wooden and acrylic pieces and engrave on the object as you like. The machine makes your work easier and more efficient.

You can get the most out of your laser cutter/engraver by selling products in the market or online stores and offering services to clients. You can make wall hangings, name tags, jewelry, tumblers, decorative items, bracelets, wallets & bags, pens, phone cases, belts, puzzles, and a lot of other things. Personalized gift items are also an excellent option as they are quite demanding for birthdays, corporate gifts, and marketing.

You can get the most out of your laser cutter/engraver by selling products in the market or online stores and offering services to clients. You can make wall hangings, name tags, jewelry, tumblers, decorative items, bracelets, wallets & bags, pens, phone cases, belts, puzzles, and a lot of other things. Personalized gift items are also an excellent option as they are quite demanding for birthdays, corporate gifts, and marketing.